METAL TEST COUPONS

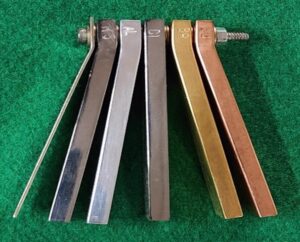

| Brake Fluid Corrosion Test | ISO 4925 MVSS -116 DOT 3,D0T 4, DOT 5 IS 8654 | Tinned iron strips | 101 | 80 x 13 x 5 thk, hole 4.0 |  |

| Steel strips | 102 | 80 x 13 x 5 thk, hole 4.0 | |||

| Aluminium alloy strip | 103 | 80 x 13 x 5 thk, hole 4.0 | |||

| Cast iron strip | 104 | 80 x 13 x 5 thk, hole 4.0 | |||

| Brass strip | 105 | 80 x 13 x 5 thk, hole 4.0 | |||

| Copper strip | 106 | 80 x 13 x 5 thk, hole 4.0 | |||

| Zinc strip | 107 | 80 x 13 x 5 thk, hole 4.0 | |||

| M.S.-Nut & Screw | 108 | 18 Long | |||

| Brake Fluid Corrosion Test | ISO 4925 SAEJ 1703 | Tinned iron strips | 109 | 80 x 13 x as purchased, hole 4.0 | |

| Steel strips | 110 | 80 x 13 x 2 thk, hole 4.0 | |||

| Aluminium alloy strip | 111 | 80 x 13 x 2 thk, hole 4.0 | |||

| Cast iron strip | 112 | 80 x 13 x 4 thk, hole 4.0 | |||

| Brass strip | 113 | 80 x 13 x 2 thk, hole 4.0 | |||

| Copper strip | 114 | 80 x 13 x 2 thk, hole 4.0 | |||

| Zinc Plated steel strip | 115 | 80 x 13 x 2 thk, hole 4.0 | |||

| M.S.-Nut & Screw | 116 | 18 Long | |||

| Brake Fluid Resistance to Oxidation | ISO 4925, SAEJ 1703 MVSS – 116 DOT 3,D0T 4, D0T 5,IS 8654 | Aluminium alloy strip (IS 737) | 117 | 80 x 13 x 5 thk, hole 4.0 |  |

| Cast iron strip (IS 3355) | 118 | 80 x 13 x 5 thk, hole 4.0 |  | ||

| M.S. – nut & screw | 119 | 12 Long ,Fillister head |  | ||

| Tinned iron strip (99.9°é) | 120 | 12 x 12 x 0.5 thk, (Avg} | |||

| Brake Fluid Test | SAEJ 7103 Annx- D, DOT 3, 4,5 IS 8654 | Standard L rubber slab TS 338/ OM 33 | 121 | 150 x 150 x 2 thk |  |

| SBR cups | 122 | 32 dia. cylinder cups |  | ||

| EPDM rubber slab stock | 123 | 150 x 150 x 2 thk | |||

| SealCompatibility Test | IS 10522 | NBR disc IS 11656 | 124 | 36 dia. 6thk |  |

| Vulcanized rubber sheet BS 439 | 125 | 150 x 120 x 2 thk | |||

| Resistance to Oxidation | IS 8654 | Aluminium alloy strip | 126 | 80 x 13 x 2 thk, hole 4.0 |

|

| Cast iron strip | 127 | 80 x 13 x 4 thk, hole 4.0 | |||

| Tin Foil | 128 | 10 x 10 x 0.02 thk | |||

| Solid Film Lubricants | FTM 791-3810, 3814,7001 | Aluminium gg-A-362 MIL-A-8265 type1 | 129 | 76 x 152 x 0.5 thk |  |

| Thermal Stability Corrosive Test Antifreeze Corrosion | MIL-L-23699B App All MIL-C-46113 | Steel | 130 | 7 x 75 x 1.5 thk | |

| Copper§§-C-576 | 131 | 12.5 x 76 x 3 thk | |||

| Steel gg-C-698 | 132 | 12.5 x 76 x 3 thk |  | ||

| Aluminum gg-A-250/4 | 133 | 12.5 x 76 x 3 thk |  | ||

| Brass g§-B-613-2 | 134 | 12.5 x 76 x 3 thk |  | ||

| Cast Iron §§-1-652-20 | 135 | 12.5 x 76 x 3 thk |  | ||

| SiIver99.9 | 136 | 12.5 x 76 x 3 thk |  | ||

| Copper Corrosion for Lubes and Liquid Fuels | IS 1448,P:15 ASTM D 130 IS0 2160 ASTM D 4048 | Copper strip grade 99.9% pure | 137 | 75 x 12.5 x 2.5 thk | |

| 138 | 75 x 12 x 2.5 thk |  | |||

| 139 | 75 x 12 x 2 thk | ||||

| Copper Corrosion for LPG | ASTM D 1838 | Copper strip grade 99.9% pure | 140 | 75 x 12 x 2 thk with hole 3.2 | |

| Effect of Grease on Copper | ASTM D 1261 | Copper strip grade 99.9% pure | 141 | 44.5 x 8 x 1.6 thk |  |

| Copper Corrosion Test | ASTM D 1275 | Copper strip grade 99.9% pure | 142 | 25 x 6 x 0.15 thk | |

| Corrosive Sulfur in Insulating Oil | DIN 51 353 | Silver 99.99 | 143 | 400 x 20 x 0.5 thk | |

| Cast Iron Corrosion | IS 1115, IP 125 | Grey cast iron plate | 144 | 100 x 100 x 6 thk |  |

| Steel MillingTest | IS 1115 | Steel milling prepared by dry milling | 145 | 6 longx 1.5-3 width |  |

| Iron Chip Corrosion | ASTM D 4627 DIN 51360-2 |

Grey cast iron chips Brinell hardness 179-217 Dry milling from high speed drill |

146 | Chips sieved thru 3.35mm and 850 ym mesh |  |

|

| Rust Prevention characteristics test for water based metal working fluids | IP 287 | Grey cast iron chips drawn dry milling from high speed drill | 147 | Chips sieved thru 3.35mm and 850 ym mesh | ||

| Studies of atmospheric Corrosion on metals | IS 5555 | Aluminium | Outdoor | 148 | 100 x 150 x 1.25 thk |  |

| Indoor | 149 | 150 x 50 x 1.25 thk | ||||

| Zinc | Outdoor | 150 | 100 x 150 x 1.25 thk | |||

| Indoor | 151 | 150 x 50 x 1.25 thk | ||||

| Aluminium | Outdoor | 152 | 100 x 150 x 1.25 thk | |||

| Indoor | 153 | 150 x 50 x 1.25 thk | ||||

| Stainless Steel | Outdoor | 154 | 100 x 150 x 1.25 thk | |||

| Indoor | 155 | 150 x 50 x 1.25 thk | ||||

| Tin | Outdoor | 156 | 100 x 150 x 1.25 thk | |||

| Indoor | 157 | 150 x 50 x 1.25 thk | ||||

| Studies of underground Corrosion on metals | IS 1808 | Cast iron pipes-horizontal C. Spun | 158 | 65 dia , 250 long | ||

| Galvanised steel pipe | 159 | 65 dia , 250 long | ||||

| MS pipe | 160 | 65 dia , 250 long | ||||

| AL pipe | 161 | 65 dia , 250 long | ||||

| MS plates | 162 | 200 x 300 x 3 thk | ||||

| Cu plates | 163 | 200 x 300 x 3 thk | ||||

| Aluminium cable | 164 | 300 long | ||||

| Lead cable | 165 | 300 long | ||||

| Wire rope lubricant test for water repellency property |

IS 9182 | Mild steel plate (IS 513) | 166 | 80 x 40 x 1.3 thk |  |

|

| Adhesion test | Mild steel panel (IS 513) | 167 | 76 x 100 x 1.3 thk |  |

||

| Temporary Corrosion | IS 1153 | Annex A : Determination of Dying Time | 168 | 76 x 38 x 1.3 thk with |  |

|

| Preventives, Hard Film | Mild Steel (IS 513) | 6mm dia hole, | ||||

| Solvent Deposited | Annex B : Low temperature Flexibility Tin Plate | 169 | 75 x 25 tin 6mm dia hole |  |

||

| Annex C : Adhesion and Stickiness Mild Steel – IS 513 | 170 | 76 x 38 x 1.3 with 6mm dia hole, |  |

|||

| Annex D : Freedom from Corrosive effect | ||||||

| I) Mild Steel – IS 513 | 171 | 50 x 25 x 2 to 3 thk |

|

|||

| ii) Brass – CuZn37 (IS 410) | 172 | 50 x 25 x 2 to 3 thk | ||||

| iii) Aluminium Alloy IS 537 | 173 | 50 x 25 x 2 to 3 thk | ||||

| iv) Magnesium Alloy Ref D 2.1.4 | 174 | 50 x 25 x 2 to 3 thk | ||||

| v) Zinc Base Alloy IS 713 | 175 | 50 x 25 x 2 to 3 thk | ||||

| Annex F: Resistance to Sagging Mild Steel – IS 513 | 177 | 150 x 100 x 1.2 thk |  |

|||

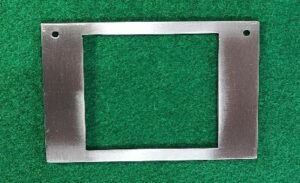

| Temporary Corrosion Preventive Fluid, Soft Film, Solvent Deposited, Water Displacing | IS 1154 | Annex A : Film thickness MS Panel – IS 513 | 178 | 60 x 80 x 2 (with 50×50 cut-out& Mo holes) |  |

| Annex B : Drainage Test MS Panel – IS 513 | 179 | 80 x 40 x 1.3 mm with 6 mm hole |  | ||

| Annex E: Water Displacement MS Panel – IS 513 | 180 | 76 x 38 x 1.25 mm in size with 6 mm dia hole |  | ||

| Annex E: Corrosive effect onb Lead Lead (99.9% min.) | 181 | 75 x 50 x 1.5 mm in size | |||

| Annex G : Freedom from Corrosive effect | |||||

| I) Mild Steel – IS 513 | 182 | 50x25x2to 3 mm in size |  | ||

| ii) Brass – CuZn37 (IS 410) | 183 | 50x25x2to 3 mm in size |  | ||

| iii) Aluminium Alloy – IS 537 | 184 | 50x25x2to 3 mm in size |  | ||

| iv) Magnesium Alloy Ref. 2.1.4 | 185 | 50x25x2to 3 mm in size |  | ||

| v) Zinc Base Alloy – IS 713 | 186 | 50x25x2to 3 mm in size |  | ||

| General purpose oil based temporary corrosion preventives | IS 14779 | Annex A : Film Thickness MS Panel – IS 513 | 187 | 60 x 80 x 2 (with 50×50 cut-out & Mo holes). |  |

| Turbine oil rust test for corrugated cargoes | ASTM D 665 IS 1448 P:96 NACETM 0172 | Steel specimen (BS970, Part I/SAE 1018) | 188 | 1/2 inch dia, US thread, 81L |  |

| PTFE holder | 189 | ||||

| PTFE beaker cover | 190 | 95.3 dia x 2.4thk | |||

| SS stirrer | 191 | 25 x 6 x 0.6thk | |||

| Method for corrosion protection test for TCP | IS 10493 | MS (IS 513) | 192 | 100 x 150 , 3mm hole |  |

| Test for protection against corrosion at high temperature & high humidity(cabinet test) | MS (IS 513) | 193 | 100 x 50 x 2.5 thk |  | |

| Brass (IS 410) | 194 | 100 x 50 x 2.5 thk |  | ||

| Aluminium alloy (US 713) | 195 | 100 x 50 x 2.5 thk |  | ||

| Test for freedom from corrosive effect on metal specimen | MgAlloy | 196 | 100 x 50 x 2.5 thk |  | |

| 196A | 50 x 25 x 2.5thk |  | |||

| Zinc base alloy(IS 713) | 197 | 100 x 50 x 2.5 thk |  | ||

| 197A | 50 x 25 x 2.5 thk |  | |||

| Test for corrosion effect on lead strip, copper strip, strippable coatings | Annealed electrolytic Cu (>99.9%) | 198 | 75 x 13 x 2 thk | ||

| Lead strip (IS 405) (Part 1) | 199 | 75 x 50 x 1.6thk | |||

| Cold finished strip (IS 513) | 200 | 75 x 50 x 2 thk | |||

| Sulphur dioxide test(IP Test) | MS (IS 513) | 201 | 150 x 50 x 0.9 thk | ||

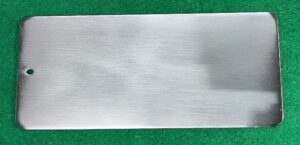

| Salt spray test | ASTM B 117 | MS panels | 202 | 127 x 76 x 0.8 thk |  |

| Metal corrosion test | MS sand blasted panels by 50 micron AI sand with 120 degree | 202A | 127 x 76 x 0.8 thk |  | |

| Metal corrosion test | Mild steel grade NIL 22698 both sides blasted panels with medium grit | 202B | 152 x 106 x 3.2 thk |  | |

| Cyclic wet/dry prohesion test | ASTM G 85 A5 | MS panels | 203 | 100 x 50 x 2 thk |  |

| Rust protection by metal preservatives in the humidity cabinet | ASTM D 1748 IP 366 | C.R. ship A 109 or (g9-S-698 Gr 1009) | 204 | 102 x 51 x 3.2 thk (Two holes 3 each) |  |

| Dummy panel SS 304. | 204A | 102 x 51 x 3.2 thk (Two holes 3 each) | |||

| Dummy panel Metha acrylic. | 204B | 102 x 51 x 3.2 thk (Two holes 3 each) |

| Engine coolant/ Antifreeze corrosion test | JIS K 2234 IS 5759 | Aluminium casting strip, JIS H 5202 | 205 | 50 x 25 x 3 thk |  |

| Cast Iron, JIS G 5501 | 206 | 50 x 25 x 3 thk | |||

| Steel strip, JIS G 3141 | 207 | 50 x 25 x 1.6 thk | |||

| Brass strip, JIS H 3100 | 208 | 50 x 25 x 1.6 thk | |||

| Solder strip, JIS Z 3282 | 209 | 50 x 25 x 3 thk | |||

| Copper strip, JIS H 3100 | 210 | 50 x 25 x 1.6 thk | |||

| Screw covered with resin | 211 | M5 x 0.8 x 60 | |||

| Synthetic spacer A, JIS K 6888 | 212 | d12 x d6.5 x 1.5 | |||

| Steel spacer B | 213 | d12 x d6.5 x 4.5 | |||

| Steel spacer C | 214 | d12 x d6.5 x 4.5 | |||

| Synthetic spacer D, JIS K 6888 | 215 | d12 x d6.5 x 4.5 | |||

| Supporting brass plate | 216 | 50 x 25 x 1.6thk | |||

| Brass nut | 217 | M5 x 0.8-6H, Hexagon | |||

| Aluminium corrosion at heat transfer surface corrosively of IC engine coolant | ASTM D 4340 JIS K 2234 IS 7029 | Cast Aluminium JIS H 5202 | 218 | 65 dia x 13thk |  |

| Engine coolant/ Antifreeze Corrosion test | ASTM D 1384 ASTM D 2570 | Aluminium casting strip UNS A03190 | 205A | 50.8 x 25.4 x 3.2 thk |  |

| Cast iron strip UNS F 10007 | 206A | 50.8 x 25.4 x 3.2 thk | |||

| Steel strip UNS G10200 | 207A | 50.8 x 25.4 x 1.6 thk | |||

| Brass strip UNS C26000 | 208A | 50.8 x 25.4 x 1.6thk | |||

| Solder strip grade 3A (SAE 3A) | 209A | 50.8 x 25.4 x 1.6 thk | |||

| Copper strip UNS C11000 | 210A | 50.8 x 25.4 x 1.6 thk | |||

| Screw covered with resin | 211A | M5 x 0.8 x 60 | |||

| Synthetic spacer A, PTFE | 212A | d12 x d6.5 x 1.5 | |||

| Steel spacer B | 213A | d12 x d6.5 x 4.5 | |||

| Steel spacer C | 214A | d12 x d6.5 x 4.5 | |||

| Synthetic spacer D, PTFE | 215A | d12 x d6.5 x 4.5 | |||

| Supporting brass plate | 216A | 50 x 25 x 1.6thk | |||

| Brass nut/ bracket | 217A | standard | |||

| Test Method for corrosion test for electrical vehicle coolants in glassware | ASTM D 8485 | Stainless Steel S30400 | 219 | 51 x 25 x 1.6 thk |  |

| Aluminium A93003 | 220 | 51 x 25 x 1.6 thk | |||

| Insulating Spacers | |||||

| Tetraflouroethylene polymer leg | 221 | ||||

| Tetraflouroethylene polymer scew & Nut | 222 | ||||

| Test Method for corrosion test for electrical vehicle coolants in glassware | ASTM D 8485 | Stainless Steel S30400 | 219A | 51 x 25 x 1.6 thk |  |

| Aluminium A93003 | 220A | 51 x 25 x 1.6 thk | |||

| Copper C11000 | 224 | 51 x 25 x 1.6 thk | |||

| Insulating Spacers | |||||

| Tetraflouroethylene polymer leg | 221A | ||||

| Tetraflouroethylene polymer scew & Nut | 222A | ||||

| Descalling agent action | IS 7029 | Mild steel strip | 225 | 50 x 25 x 1.2 thk |  |

| Copper strip | 226 | 50 x 25 x 1.2 thk |  | ||

| Brass strip | 227 | 50 x 25 x 1.2 thk |  | ||

| Cast iron strip | 228 | 50 x 25 x 1.2 thk |  | ||

| Aluminum strip | 229 | 50 x 25 x 1.2 thk |  | ||

| Solder: 70% Lead, 30% Tin | 230 | 50 x 25 x 1.2 thk |  | ||

| Corrosion inhibition test | IS 7029 | Aluminium strip | 231 | 37.5 x 25 x 1.2 thk |  |

| Copper strip | 232 | 37.5 x 25 x 1.2 thk |  | ||

| Mild steel strip | 233 | 37.5 x 25 x 1.2 thk |  | ||

| Lead coated mild steel | 234 | 37.5 x 25 x 1.2 thk | |||

| Solder coated mild steel | 235 | 37.5 x 25 x 1.2 thk |  | ||

| Turbine oil oxidation test | ASTM D 934 DIN 51587 | Steel wire | 236 | 1.6 dia. | |

| Copper wire | 237 | 1.6 dia. |  | ||

| Wire coiling mandrel, brass & steel | 238 | As per ASTM D 943 | |||

| SS thermometer bracket | 239 | 22 Gauge | |||

| Badder oil ageing stability test | DIN 51 554 | Electrolytic copper DIN 46431E-Cu20-2 | 240 | 2 dia. 300 long | |

| Oxidation test of mineral oil | IP306,307,331,335, ASTM D 2240, IEC 813 | Electrolytic copper 99.9% pure grade | 241 | 1.04 dia. |  |

| Fire resistant fuel corrosion test | IP 331 | Steel wire | 236 | 1 dia. | ||||

| Test for corrosiveness and oxidation stability of oils & hydraulic fluid | Defense standard 05:50 part 29 | Magnesium alloy strips BS 3370 MAG-S- 111 | 237 | 25 x 25 x 3 thk, holes 1.5 |  | |||

| Steel strips BS 1449 Part 1,CR1FF | 238 | 25 x 25 x 3 thk, holes 1.5 | ||||||

| Descaling agent action | Aluminium alloy strip BSL 156 | 239 | 25 x 25 x 3 thk, holes 1.5 |  | ||||

| Cadmium plated steel BS 1449 Part 1 | 240 | 25 x 25 x 3 thk, holes 1.5 | ||||||

| Copper strip BS 1432 C 103 | 241 | 25 x 25 x 3 thk, holes 1.5 | ||||||

| Inert cord to assemble the strips | 242 | 1.5 dia. | ||||||

| General purpose test/ Metal corrosion test | Magnesium strip, Mg alloys gg M-44 | 243 | 70 x 50 x 2 thk | |||||

| Titanium specimen, Titanium grade 2 | 244 | 70 x 50 x 2 thk | ||||||

| Pure electrolytic tough pitch copper rod | 245 | 6.25 dia. 76.2 L | ||||||

| Steel Rod AISIW-1 1 °é carbon steel | 246 | 6.25 dia. 76.2 L | ||||||

| Mild steel rod | 247 | 10 dia. 50 L | ||||||

| Mild steel panels as per IS 513 | 248 | 50 x 25 x 2 thk |  | |||||

| Copper strip as per IS 1972 | 249 | 50 x 25 x 2 thk |  | |||||

| Cast iron panels as per IS 3005 | 250 | 50 x 25 x 2 thk |  | |||||

| Brass strip as per IS 410 | 251 | 50 x 25 x 2 thk |  | |||||

| SS strip as per IS 6911 | 252 | 50 x 25 x 2 thk |  | |||||

| Cupro-nickel strip as per IS 3052 | 253 | 50 x 25 x 2 thk |  | |||||

| Carbon steel panels, C 1018 | 254 | 37 x 15 x 2 thk | ||||||

| Aluminium strip grade 1015 | 255 | 150 x 100 x 2.5 | ||||||

| Aluminium strip grade IS 7029 | 256 | 100 x 50 x 2.5 thk | ||||||

| Steel strip grade N 80 | 257 | 64 x 25 x 4 thk | ||||||

| Zinc strip grade 99.5% pure831 | 258 | 100 x 20 x 2 thk | ||||||

| Weld load measurement test | ASTM D 2783 ASTM D 2516 | Chrome alloy steel balls EP grade 25 64-66 Rockwell Hardness | 259 | 12.7 dia. ball |  | |||

| Petri Dish with lid | Aluminium | 260 | 4 Inch Diameter |  | ||||

| Aluminium Alloys | Aluminium 380 | 30 | 50 x 25 x 2 thk |  | ||||

| Aluminium 1100 | 1004 | 50 x 25 x 2 thk | ||||||

| Aluminium 1199 | 1005 | 50 x 25 x 2 thk | ||||||

| Aluminium 2011 | 2001 | 50 x 25 x 2 thk | ||||||

| Alumium 2024 | 2003 | 50 x 25 x 2 thk | ||||||

| Aluminium 3003 | 3001 | 50 x 25 x 2 thk | ||||||

| Aluminium 3004 | 3002 | 50 x 25 x 2 thk | ||||||

| Aluminium 5050 | 5005 | 50 x 25 x 2 thk | ||||||

| Aluminium 6061 | 6001 | 50 x 25 x 2 thk | ||||||

| Aluminium 7075 | 7002 | 50 x 25 x 2 thk | ||||||

| Polymers / Elastomers | Nitrile Butadiene Rubber | E210 | 100 x 100 x 2 to 5 mm | |||||

| Polyurethane | E211 | 100 x 100 x 2 to 5 mm | ||||||

| Fluorosilicon | E212 | 100 x 100 x 2 to 5 mm | ||||||

| Fluorocarbon | E213 | 100 x 100 x 2 to 5 mm | ||||||

| Epoxy Graphite | E214 | 100 x 100 x 2 to 5 mm | ||||||

| Acrylic Nitrile | E215 | 100 x 100 x 2 to 5 mm | ||||||

| Acrylic Nitrile | E216 | 100 x 100 x 2 to 5 mm | ||||||

| Epichlorohydrin | E217 | 100 x 100 x 2 to 5 mm | ||||||

| Nylon 101 | E218 | 100 x 100 x 6 mm and above | ||||||

| High Density Polyethylene | E219 | 100 x 100 x 2 to 5 mm | ||||||

| Acrylonitrile Butadiene | E220 | 100 x 100 x 2 to 5 mm | ||||||

| Chloroprene | E221 | 100 x 100 x 2 to 5 mm | ||||||

| Ehhylene Propylene Diene Monomer (EPDM) | E222 | 100 x 100 x 2 to 5 mm | ||||||

| Natural Rubber | E223 | 100 x 100 x 2 to 5 mm | ||||||

| Soft PVC Resin | E224 | 100 x 100 x 2 to 5 mm | ||||||

| ABS Resin | E225 | 100 x 100 x 2 to 5 mm | ||||||

| Poly Tetra Fluoroethylene (PTFE) | E226 | 100 x 100 x 2 to 5 mm | ||||||

| Hydrogenerated Nitrile Butadiene (HNBR) | E227 | 100 x 100 x 2 to 5 mm | ||||||

| Styrene Butadiene Rubber (SBR) | E228 | 100 x 100 x 2 to 5 mm | ||||||

| Epichlorohydrin | E229 | 100 x 100 x 2 to 5 mm | ||||||

| Polyvinyl Chloride | E230 | 100 x 100 x 2 to 5 mm | ||||||

| Polypropylene | E231 | 100 x 100 x 2 to 5 mm | ||||||