CHANNELING CHARACTERISTICS OF LUBRICANTS

CHANNELING CHARACTERISTICS OF LUBRICANTS – FED-STD-791 / 3456.2 / IS 1118

Model Code: SEWCL01. (Liquid bath 4 place assembly)

SEWCL02. (Liquid bath 6 place assembly)

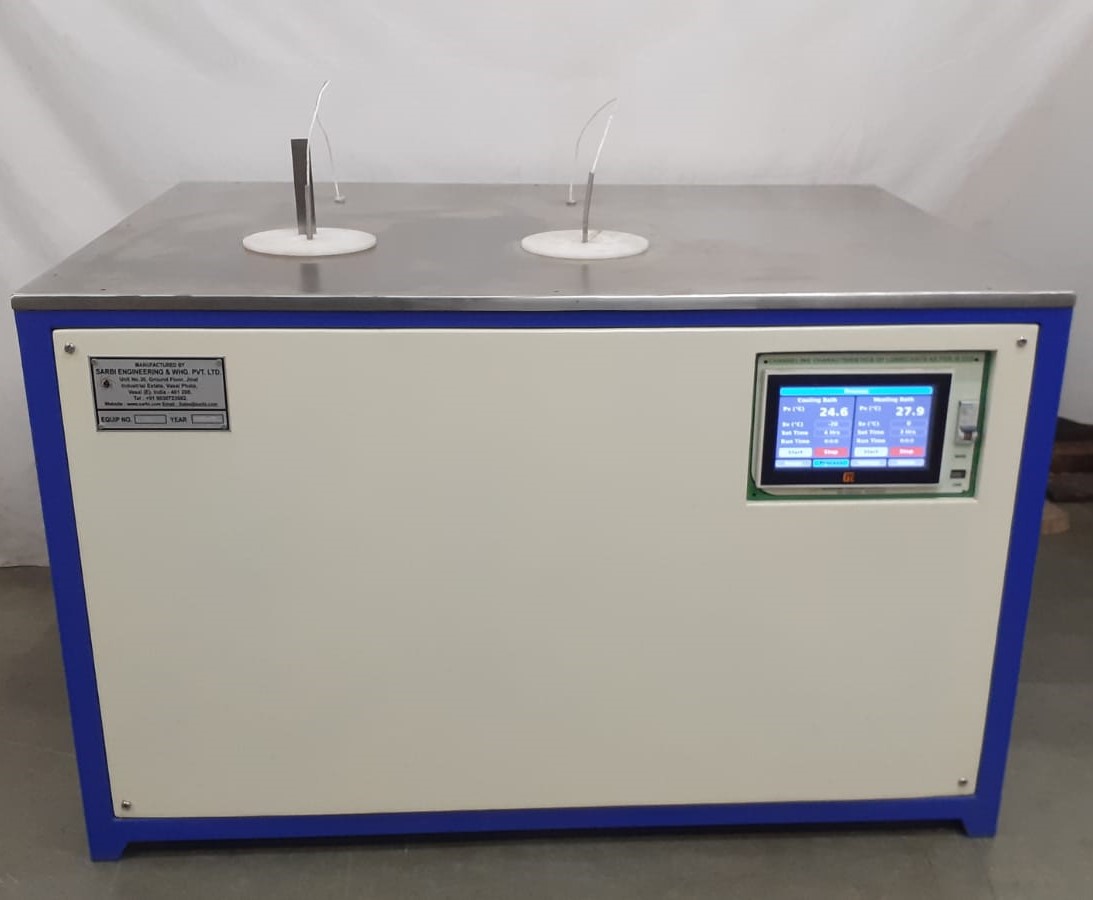

SEWFC03 (Twin air bath 2 test cylinder)

SEWCL03. (Liquid bath 8 place assembly)

Channel point is the lowest safe temperature that a gear lubricant can be used. The test apparatus is used for storing the samples for 18 hours at the temperature specified in test standard. The sample procedure is followed by cutting a channel in the lubricants with a metal strip, and determining whether the lubricant flows together to cover the bottom of the container within 10 seconds.

APPARATUS CONSIST OF :

| Twin bath | The constant temperature liquid baths with cooling and heating arrangement. |

| Constant low temp bath | The constant temp. liquid baths with cooling & heating arrangement SS/MS. |

| Cooling assembly | Hermetically sealed compressor, fan motor, condenser, CFC free refrigerant etc. |

| Heating assembly | Emersion type electrical heater, overload protector, etc. |

| Test containers | Borosilicate mfg, standard dimension with cover, thermometer, steel strip, etc. |

| Control panel | Digital temperature indicator cum controller, both for low / high temp. time totalizer. |

| Power supply | CFPPElectrical supply switches: 2 Nos. 220/240 V, 15 amp, 1 phase. |

| Recommended Spares | ASTM 12 C Thermometer. Glass test containers. Cutting Steel Strips PC / Laptop, etc. |